011.20.200

LNB

120 mm

280 mm

60 mm

Steel

External Gear Type Slewing Bearing

China

OEM; ODM

Negotiation

30

| Availability: | |

|---|---|

| Basic Information | |

| Model | 011.20.200 |

| Brand | LNB |

| System of Measurement | Metric |

| Bearing Type | Slewing Bearing |

| Gear Type | External Gear Type |

| Weight | 20.00 kg |

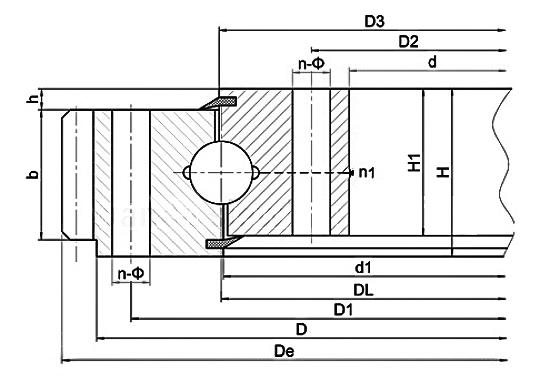

| Product Dimension | |

| Outer Diameter With Teeth (De) | 300 mm |

| Outer Diameter (D) | 280 mm |

| Inner Diameter (d) | 120 mm |

| Overall Width (H) | 60 mm |

| Mounting Dimension | |

| Center Circle Diameter-Outer Ring (D1) | 248 mm |

| Center Circle Diameter-Inner Ring (D2) | 152 mm |

| Diameter of Through Holes (φ) | 16 mm |

| Diameter of Threaded Holes (M) | M14 |

| Depth (L) | 28 mm |

| Number of Holes (n) | 12 |

| Structural Dimension | |

| Number of lubricating holes (n1) | 2 |

| Outer Diameter of Inner Ring (D3) | 201 mm |

| Inner Diameter of Outer Ring (d1) | 199 mm |

| Width of Outer Ring (H1) | 50 mm |

| Width difference at bottom (h) | 10 mm |

| Gear data | |

| Gear Tooth Width (b) | 40 mm |

| Displacement Coefficient (x) | 0 |

| Modulus (m) | 3 |

| Number of gear teeth (z) | 98 |

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2. According to the user's application, the Oil nipple's location can be changed.

2. n-φ can change to a tapped hole, the diameter of the tapped hole is M, depth is 2M.

3. LNB company's product specifications are standard products, and the inner and outer diameters are free tolerances. If you have other special requirements, please contact us.

Slewing bearings are also called turntable bearings, rotating bearings, and slewing ring bearings. They are large bearings that can withstand combined loads (withstand large axial, radial loads, and overturning moments at the same time), so they are applied in a variety of applications. The slewing bearing has a simple installation and upkeep process. Its design is space-efficient, with seals on both sides. And you can add grease through a special nozzle to lubricate the slewing bearings.

There are many types of slewing bearings, and four-point contact slewing bearing stands out as a common type among slewing bearings. It can handle heavy loads.

The four-point contact ball slewing bearing has a straightforward structure. It includes an outer ring, an inner ring, steel balls (rolling elements), spacers, and seals. The inner and outer ring raceways have two arc grooves. When the steel balls move in these grooves, they touch the inner and outer rings at four points. This four-point contact lets it withstand different loads at once, including axial, radial, and overturning forces. This design works well for equipment with medium loads and slow speeds. They can be used in tower cranes, construction gear, port machines, and diggers, etc.

The most common type in four-point contact ball slewing bearings has a simple structure and low manufacturing cost, usually used for equipment with medium loads and low speeds.

Having a stronger load-bearing capacity than single-row bearings, and works well in applications with large loads and high rigidity.

Mainly designed to divide the inner ring or outer ring of the bearing into two parts. Facilitates the bearings' installation and removal, and is suitable for where frequent maintenance is required.

Gearless structure, able to carry loads from different directions. But cannot directly transmit torque, if required to do that, this type of bearings needs to cooperate with external transmission devices such as motors or gearboxes to achieve rotational motion. It is commonly used in applications such as some automation equipment, rotary workbenches, etc., with high load-bearing requirements but no transmission function.

Gears are designed on the inner ring, they are meshing with the gears of the internal drive system. The internal gear four-point contact ball slewing bearing can save external space and reduce the interference of the external environment on the gear. It is good at equipment with compact space and high transmission accuracy requirements, such as tower cranes, excavators, and joints of some industrial robots.

The external gear design arranges the gear structure on the outer ring and directly meshes with the gear of the external drive system. And are easy to maintain and replace. They are useful for equipment such as large cranes, construction machinery, wind turbines, etc., with larger spaces.

The non-standard customized four-point contact ball slewing bearing, as its name suggests, is designed to meet specific special application needs. Customers have the option to tailor the size, material, raceway structure, and gear form, among other features to make the bearing to suit particular working conditions or equipment specifications.

(1) Simple structure, low manufacturing cost, and easy installation.

(2) Multi-directional load-bearing capacity, able to withstand axial, radial, and overturning moments at the same time, especially suitable for complex load situations.

(3) Have stronger load-bearing capacity under medium load conditions compared to other types of slewing bearings

LNB Bearing is a Chinese manufacturer and supplier of a wide range of bearings, which always provide great performance and quality-built bearings, winning lots of trust from worldwide customers. We have decades of experience in manufacturing and selling bearings. We can provide:

Through advanced manufacturing processes and high-quality materials, the LNB bearing is designed to be able to meet all the different requirements of customers. Our bearings are stable under extremely high load, speed, and environmental conditions. The LNB bearing features high wear resistance, corrosion resistance, fatigue resistance, etc., which effectively ensures that it can work well after long-term use to reduce equipment and device failure rates as well as maintenance costs.

A comprehensive range of LNB bearings includes ceramic bearings, deep groove ball bearings, thin section bearings, angular contact bearings, cylindrical roller bearings, tapered roller bearings, miniature bearings, spheric rollers bearings, and so on. Our bearing products are in various forms over multiple materials/types/sizes/models to fit a variety of industries and diverse application fields. For the automotive industry, large-scale mechanical equipment or precision instruments and skateboard wheels.etc., LNB bearing there are suitable products for you.

LNB bearing not only offers the best quality products but is also specific in great service to support satisfied experiences for customers. LNB bearings are available in OEM or ODM, keeping constant investment in R&D and technology improvement to offer the ideal product for our customers. At the same time, LNB bearings have been continuously innovated in materials and other sealing technologies such as dustproof and waterproof design to offer more comprehensive solutions for users.

LNB bearings always follow the concept of eco-friendly and sustainable development. Throughout product designing and manufacturing, LNB bearings emphasize energy saving and pollution reduction to minimize the harm caused by its operations on the environment. Meanwhile, LNB bearings also play a significant role in the innovation of recyclable products and reuse systems to support sustainability.

LNB Bearings Company has always been a leader in the provision of bearings and services to our customers with competitive price levels. We are exporting products around the world now. LNB has full formal channels for many well-known brands of bearings, such as SKF、NSK、FAG 、TIMKEN, etc., so customers can choose suitable bearings in different price brackets to better meet their needs.

| Basic Information | |

| Model | 011.20.200 |

| Brand | LNB |

| System of Measurement | Metric |

| Bearing Type | Slewing Bearing |

| Gear Type | External Gear Type |

| Weight | 20.00 kg |

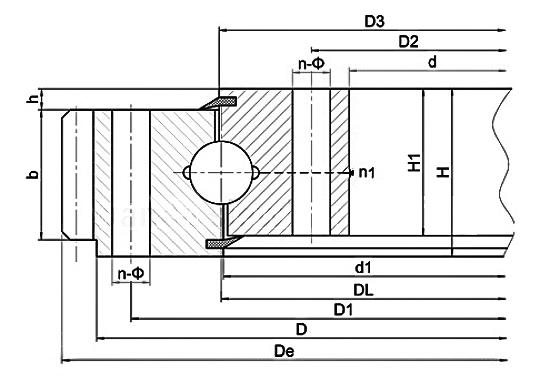

| Product Dimension | |

| Outer Diameter With Teeth (De) | 300 mm |

| Outer Diameter (D) | 280 mm |

| Inner Diameter (d) | 120 mm |

| Overall Width (H) | 60 mm |

| Mounting Dimension | |

| Center Circle Diameter-Outer Ring (D1) | 248 mm |

| Center Circle Diameter-Inner Ring (D2) | 152 mm |

| Diameter of Through Holes (φ) | 16 mm |

| Diameter of Threaded Holes (M) | M14 |

| Depth (L) | 28 mm |

| Number of Holes (n) | 12 |

| Structural Dimension | |

| Number of lubricating holes (n1) | 2 |

| Outer Diameter of Inner Ring (D3) | 201 mm |

| Inner Diameter of Outer Ring (d1) | 199 mm |

| Width of Outer Ring (H1) | 50 mm |

| Width difference at bottom (h) | 10 mm |

| Gear data | |

| Gear Tooth Width (b) | 40 mm |

| Displacement Coefficient (x) | 0 |

| Modulus (m) | 3 |

| Number of gear teeth (z) | 98 |

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2. According to the user's application, the Oil nipple's location can be changed.

2. n-φ can change to a tapped hole, the diameter of the tapped hole is M, depth is 2M.

3. LNB company's product specifications are standard products, and the inner and outer diameters are free tolerances. If you have other special requirements, please contact us.

Slewing bearings are also called turntable bearings, rotating bearings, and slewing ring bearings. They are large bearings that can withstand combined loads (withstand large axial, radial loads, and overturning moments at the same time), so they are applied in a variety of applications. The slewing bearing has a simple installation and upkeep process. Its design is space-efficient, with seals on both sides. And you can add grease through a special nozzle to lubricate the slewing bearings.

There are many types of slewing bearings, and four-point contact slewing bearing stands out as a common type among slewing bearings. It can handle heavy loads.

The four-point contact ball slewing bearing has a straightforward structure. It includes an outer ring, an inner ring, steel balls (rolling elements), spacers, and seals. The inner and outer ring raceways have two arc grooves. When the steel balls move in these grooves, they touch the inner and outer rings at four points. This four-point contact lets it withstand different loads at once, including axial, radial, and overturning forces. This design works well for equipment with medium loads and slow speeds. They can be used in tower cranes, construction gear, port machines, and diggers, etc.

The most common type in four-point contact ball slewing bearings has a simple structure and low manufacturing cost, usually used for equipment with medium loads and low speeds.

Having a stronger load-bearing capacity than single-row bearings, and works well in applications with large loads and high rigidity.

Mainly designed to divide the inner ring or outer ring of the bearing into two parts. Facilitates the bearings' installation and removal, and is suitable for where frequent maintenance is required.

Gearless structure, able to carry loads from different directions. But cannot directly transmit torque, if required to do that, this type of bearings needs to cooperate with external transmission devices such as motors or gearboxes to achieve rotational motion. It is commonly used in applications such as some automation equipment, rotary workbenches, etc., with high load-bearing requirements but no transmission function.

Gears are designed on the inner ring, they are meshing with the gears of the internal drive system. The internal gear four-point contact ball slewing bearing can save external space and reduce the interference of the external environment on the gear. It is good at equipment with compact space and high transmission accuracy requirements, such as tower cranes, excavators, and joints of some industrial robots.

The external gear design arranges the gear structure on the outer ring and directly meshes with the gear of the external drive system. And are easy to maintain and replace. They are useful for equipment such as large cranes, construction machinery, wind turbines, etc., with larger spaces.

The non-standard customized four-point contact ball slewing bearing, as its name suggests, is designed to meet specific special application needs. Customers have the option to tailor the size, material, raceway structure, and gear form, among other features to make the bearing to suit particular working conditions or equipment specifications.

(1) Simple structure, low manufacturing cost, and easy installation.

(2) Multi-directional load-bearing capacity, able to withstand axial, radial, and overturning moments at the same time, especially suitable for complex load situations.

(3) Have stronger load-bearing capacity under medium load conditions compared to other types of slewing bearings

LNB Bearing is a Chinese manufacturer and supplier of a wide range of bearings, which always provide great performance and quality-built bearings, winning lots of trust from worldwide customers. We have decades of experience in manufacturing and selling bearings. We can provide:

Through advanced manufacturing processes and high-quality materials, the LNB bearing is designed to be able to meet all the different requirements of customers. Our bearings are stable under extremely high load, speed, and environmental conditions. The LNB bearing features high wear resistance, corrosion resistance, fatigue resistance, etc., which effectively ensures that it can work well after long-term use to reduce equipment and device failure rates as well as maintenance costs.

A comprehensive range of LNB bearings includes ceramic bearings, deep groove ball bearings, thin section bearings, angular contact bearings, cylindrical roller bearings, tapered roller bearings, miniature bearings, spheric rollers bearings, and so on. Our bearing products are in various forms over multiple materials/types/sizes/models to fit a variety of industries and diverse application fields. For the automotive industry, large-scale mechanical equipment or precision instruments and skateboard wheels.etc., LNB bearing there are suitable products for you.

LNB bearing not only offers the best quality products but is also specific in great service to support satisfied experiences for customers. LNB bearings are available in OEM or ODM, keeping constant investment in R&D and technology improvement to offer the ideal product for our customers. At the same time, LNB bearings have been continuously innovated in materials and other sealing technologies such as dustproof and waterproof design to offer more comprehensive solutions for users.

LNB bearings always follow the concept of eco-friendly and sustainable development. Throughout product designing and manufacturing, LNB bearings emphasize energy saving and pollution reduction to minimize the harm caused by its operations on the environment. Meanwhile, LNB bearings also play a significant role in the innovation of recyclable products and reuse systems to support sustainability.

LNB Bearings Company has always been a leader in the provision of bearings and services to our customers with competitive price levels. We are exporting products around the world now. LNB has full formal channels for many well-known brands of bearings, such as SKF、NSK、FAG 、TIMKEN, etc., so customers can choose suitable bearings in different price brackets to better meet their needs.

content is empty!